Machinery

Quality Screw Machine Products, Inc. offers a wide array of screw machine services using our complete range of automated and manual equipment. From high volume CNC lathes, to secondary milling and drilling machines, to our stable of rebuilt multiple-spindle bar machines, Quality is ready to meet your specialized parts needs with the following machinery:

CNC Lathes

Vertical Milling

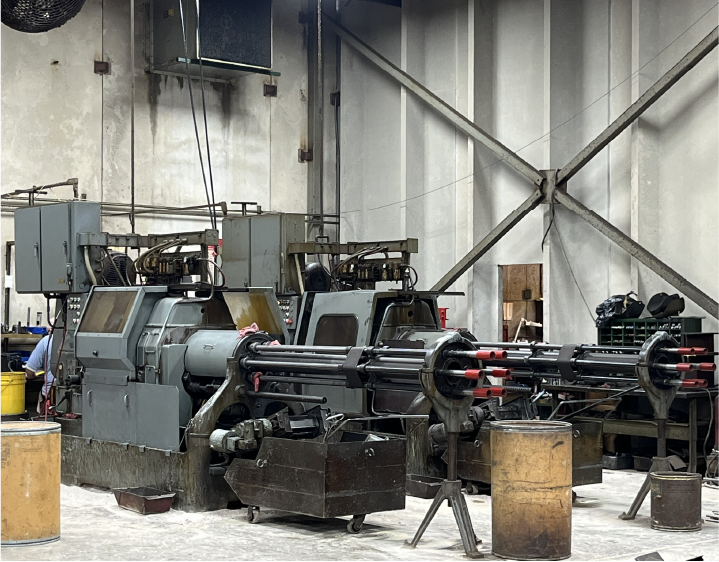

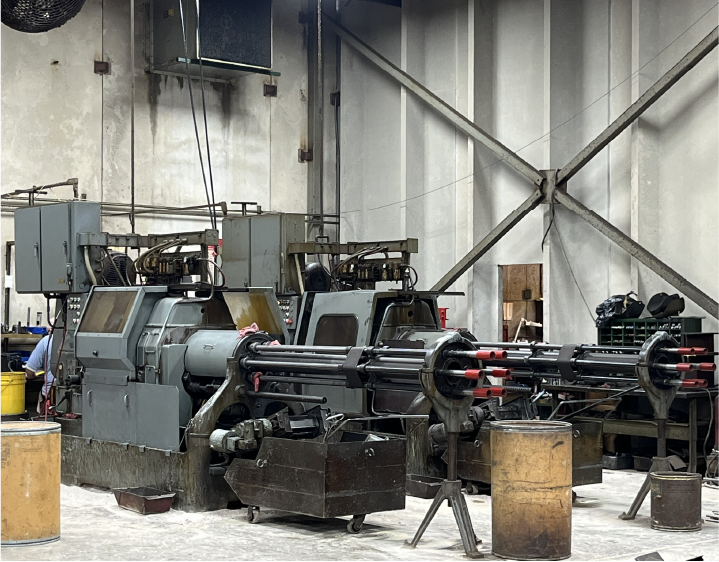

18 ACME-GRIDLEY MULTIPLE-SPINDLE BAR MACHINES

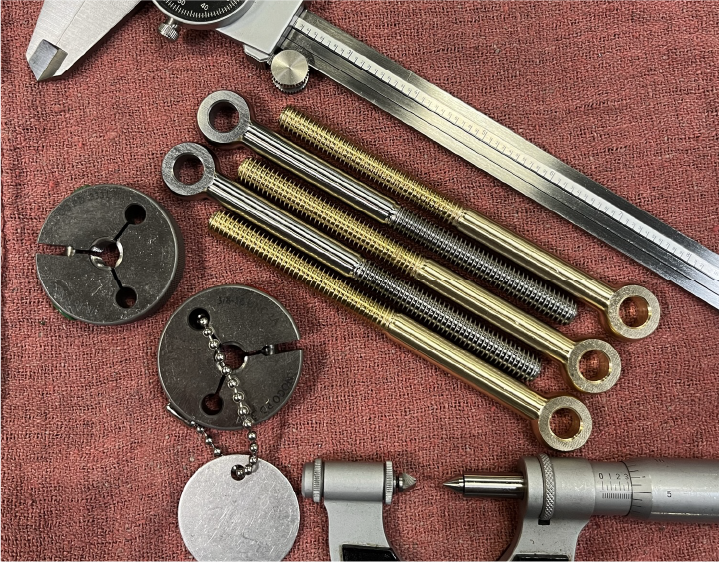

The ACME-Gridley Multiple-Spindle Bar Machine is your go-to solution for high-volume, precision machining of bar stock. Engineered for efficiency, this machine specializes in delivering consistent, top-quality parts at rapid speeds, making it ideal for manufacturers requiring large-scale production without compromising on accuracy.

All 18 of our Acme-Gridley’s are capable of tapping and O.D. threading. Additional processes include pick-off and back finishing, recessing, stenciling, high-speed drilling, knurling, and thread rolling.

Ranging from 1” to 3.5”

CAPABILITIES

1.0″ capacity RAN-6

1-1/4″ capacity RA-6

1-5/8″ capacity RB-8

2.0″ capacity RB-8

2-5/8″ capacity RB-6

3-1/2″ capacity RB-6

KEY FEATURES

Multiple Spindles for High Productivity: With multiple spindles working simultaneously, the ACME-Gridley reduces cycle time, boosting throughput and maximizing operational efficiency.

Versatility in Material Processing: Whether you’re working with steel, brass, aluminum, or other materials, this machine handles a variety of bar stock sizes and materials with ease.

Precision Machining: Thanks to its advanced design, the ACME-Gridley delivers exceptional precision on every part, ensuring consistency across high-production runs.

Durability and Reliability: Built with robust construction, this machine is designed to withstand continuous operation, making it a dependable workhorse in any production environment.

Customizable Tooling Options: Tailor the machine to meet your specific production needs with a range of tooling configurations, enhancing its versatility.

6 TSUGAMI SWISS TURNING MACHINES

Tsugami Swiss Turning Machines are renowned for their ability to produce high-precision, complex parts with exceptional speed and accuracy. Designed for tight-tolerance machining, these machines are ideal for manufacturing intricate components across a variety of industries where precision is non-negotiable.

All 6 of our machines are ideal for industries such as medical, aerospace, automotive, and electronics, where the demand for small, intricate parts with high accuracy is critical. From complex medical devices and surgical instruments to precision automotive components, these machines can handle a wide variety of challenging materials, including stainless steel, titanium, and specialized alloys.

CAPABILITIES

20 MM

32 MM

38 MM

We can run diameters from .093” to 1.5”.

KEY FEATURES

Swiss-Type Precision: The sliding headstock design of Tsugami Swiss machines allows for unparalleled precision, making them ideal for producing small, intricate parts with tight tolerances.

Multi-Axis Capabilities: Equipped with advanced multi-axis machining capabilities, these machines can perform simultaneous operations such as turning, drilling, and milling in a single setup, reducing cycle times and increasing efficiency.

Ideal for Long, Thin Parts: Tsugami Swiss machines excel at machining long, slender components with minimal deflection, ensuring consistent quality and surface finishes.

High-Speed Production: Designed for continuous, unattended operation, Tsugami machines offer fast production speeds without sacrificing accuracy, making them perfect for high-volume manufacturing environments.

User-Friendly Controls and Setup: These machines feature intuitive controls and quick tool changeovers, allowing operators to reduce downtime and increase productivity.

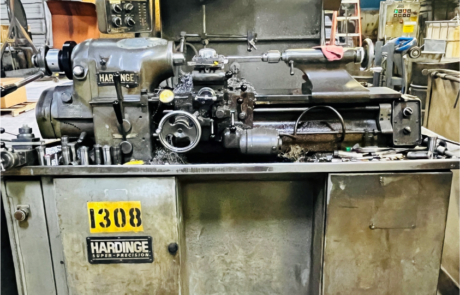

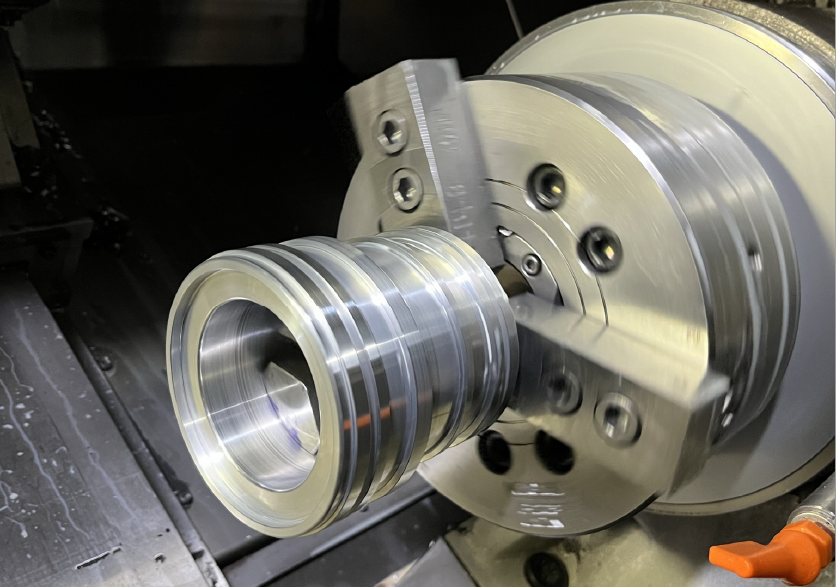

CNC LATHES

CNC Lathe Machines are the cornerstone of modern precision machining, offering unmatched versatility and accuracy for a wide range of applications. These computer-controlled machines automate the turning process, allowing for the efficient production of complex parts with tight tolerances.

CNC Lathe Machines are widely used in industries such as automotive, aerospace, electronics, and medical manufacturing, where precision, speed, and repeatability are paramount. Whether producing intricate components like gears, fasteners, or high-precision shafts, these machines deliver reliable performance for both high-volume production and custom machining.

CAPABILITIES

2 Okuma LB3000 EX2-MYW with Subspindle, and Live Tools

Okuma Genos 400 with Tail Stock

Haas ST-10Y Lathe

Haas ST-10 Lathe

Max Bar Capacity is 3.125”

Saw Cuts up to 9” diameter

KEY FEATURES

Precision and Consistency: With computer numerical control (CNC) technology, these lathes deliver consistent, high-precision results, ensuring every part meets exact specifications, even in large production runs.

Automated Efficiency: CNC lathes are designed for continuous, unattended operation, optimizing workflow and reducing labor costs while maintaining superior quality and accuracy.

Multi-Axis Capabilities: Capable of handling complex geometries, CNC lathes can perform multiple operations—such as turning, boring, threading, and facing—in a single setup, significantly reducing cycle times.

Wide Range of Material Compatibility: From metals like steel, aluminum, and brass to plastics and composite materials, CNC lathes can handle a broad spectrum of materials with ease, making them versatile for any manufacturing need.

Ease of Programming and Setup: CNC lathes feature user-friendly interfaces and can easily be programmed for specific jobs, allowing for quick setup and changeover between projects, minimizing downtime.

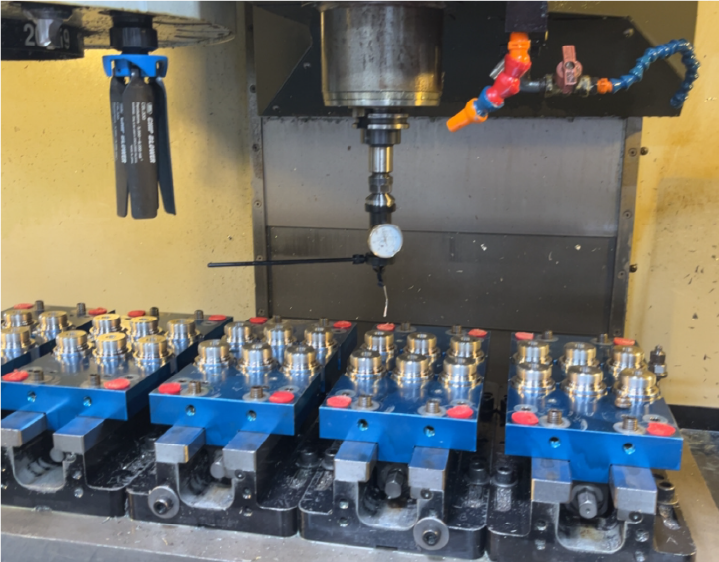

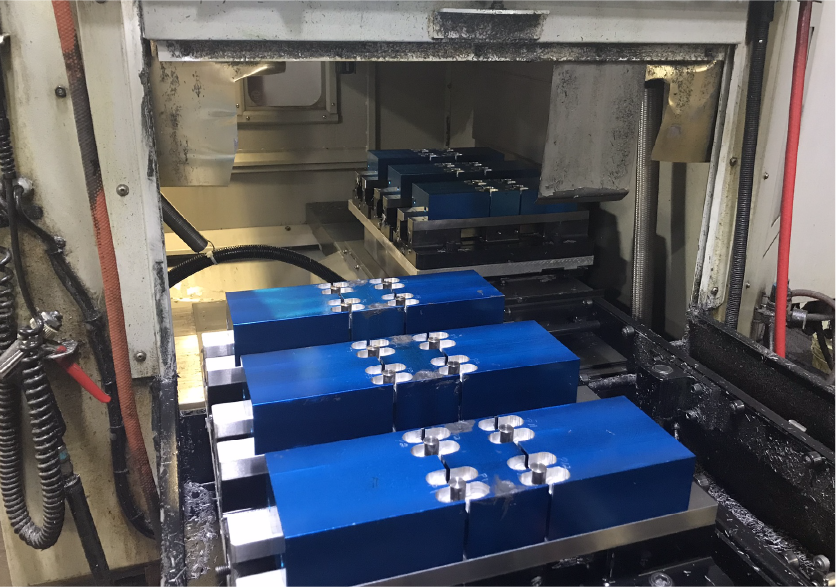

VERTICAL MILLING CENTERS

Vertical Milling Centers (VMCs) are essential machines for precision machining, offering versatility and efficiency in milling, drilling, and boring applications. With their vertical spindle orientation, VMCs excel at producing complex parts with tight tolerances, making them a key asset in modern manufacturing.

Vertical Milling Centers are used across a wide range of industries, including aerospace, automotive, medical device manufacturing, and general machining. They are ideal for producing precision parts such as molds, dies, engine components, and intricate prototypes. VMCs are especially useful in applications requiring detailed contours, slots, holes, and surface finishes.

CAPABILITIES

Haas VF-3 Vertical Mill with Pallet Shuttle

Haas VF-O with 4th Axis

Bridgeport/Hardinge Vertical Mill with Midaco Pallet Shuttle

10,000 Max RPM

KEY FEATURES

High Precision and Accuracy: Vertical Milling Centers deliver exceptional accuracy and repeatability, ensuring consistent part quality even in complex geometries and high-precision applications.

Versatile Machining Capabilities: These machines are designed to handle a wide variety of materials, from metals like steel and aluminum to plastics and composites, allowing manufacturers to take on diverse projects with ease.

Multi-Axis Operation: VMCs offer multi-axis capabilities, enabling complex milling, drilling, and boring operations in a single setup. This reduces cycle times and enhances production efficiency.

Automated and User-Friendly: Equipped with CNC controls, VMCs allow for automation of repetitive tasks, improving productivity while reducing the need for manual intervention. Their intuitive interfaces make setup, programming, and tool changes quick and straightforward.

Durability and Rigidity: Built with robust construction, VMCs are engineered to withstand heavy-duty operations, providing the stability and rigidity needed for high-performance machining over extended periods.